Reimagining the future of prosthetic innovation

Aurius Prosthetics is redefining accessibility through open-source, 3D-printed prosthetic solutions — empowering individuals with microtia to express themselves with confidence, affordability, and individuality.

Our mission is to revolutionize accessibility and personalization in prosthetic ear design through cutting-edge 3D printing technology. We strive to provide affordable, accessible, and aesthetically realistic solutions for individuals with microtia, empowering them with greater confidence and self-expression.

1/6000 people live with microtia, a congenital condition where the external ear is absent or underdeveloped. Additionally, millions of people experience unfortunate ear deformities from accidents, burns, or other conditions. By leveraging innovative materials and user-centered design, we aim to make reconstructive technology accessible to the entire world, ensuring that every individual has access to high-quality, customizable prosthetics that seamlessly integrate into their lives.

Our Mission

Step-By-Step Process

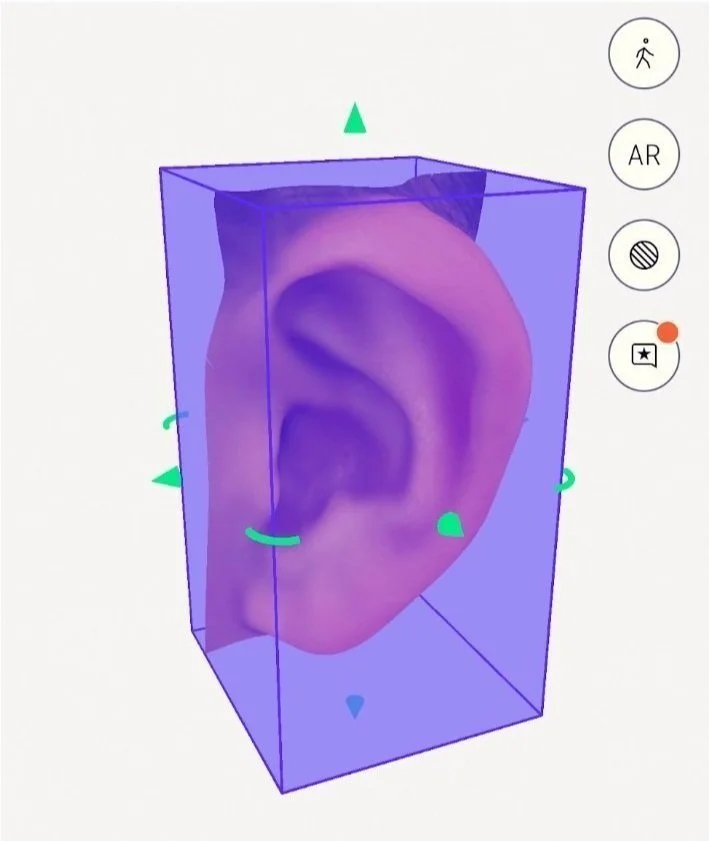

LiDAR Technologies

Using LiDAR technology, we capture highly detailed 3D renders of the ear. The scans are meticulously examined to isolate the ear geometry, ensuring precise anatomical fidelity for custom prosthetic modeling.

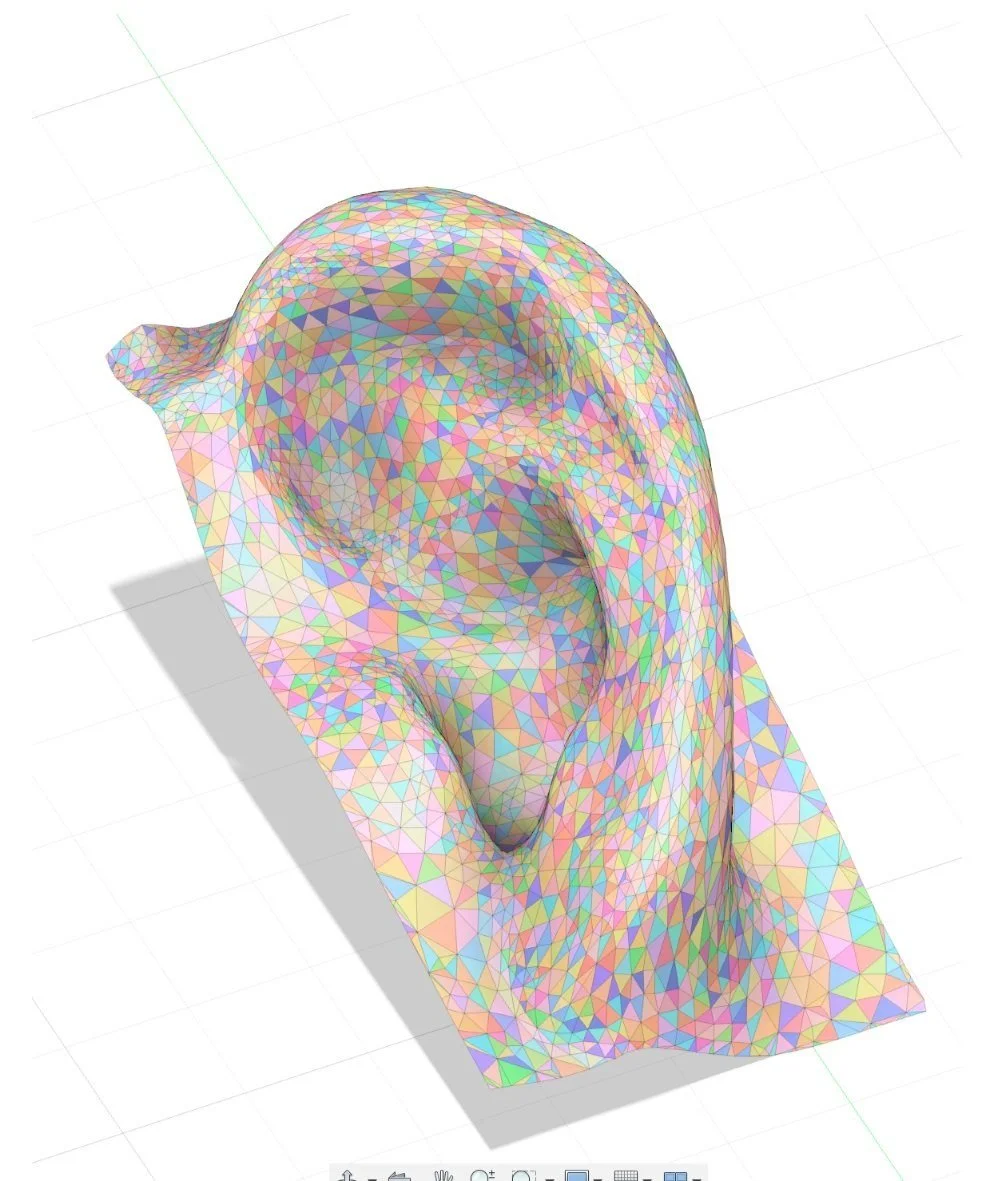

3D Render and Design

The LiDAR scans are exported as STL files and refined using CAD. We utilize design software like Fusion 360 and MeshMixer. These tools are used to repair any surface imperfections and to transform the raw rendering into a into print-ready, high-resolution digital model.

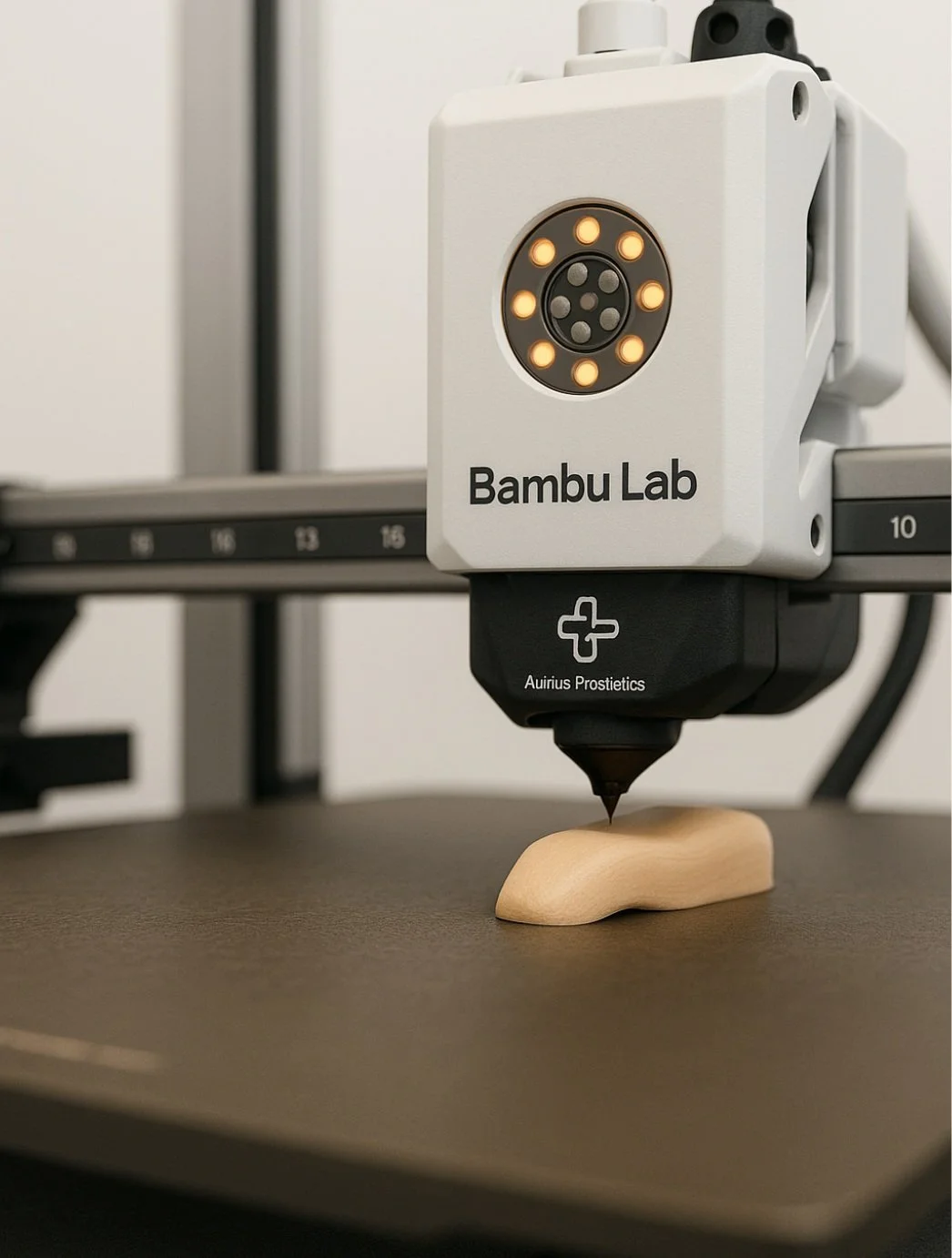

Printing and Manufacturing

Our models are able to be printed on widely-available commercial 3D printers. We utilize flexible and prosthetic grade TPU filament for lifelike, soft-touch final prints. Through extensive testing and fine-tuning, we are able to produce prints that mimic the natural feel and structure of the human ear.